FRIGGITRICI

Professionalità e competenza

La nostra produzione raggiunge i mercati esteri e ci inseriamo da protagonisti. Abbiamo clienti in tutto il mondo che friggono: prodotti di carnevale, krapfen, pellets, patate, arachidi

Da sempre la nostra attenzione ai suggerimenti , la collaborazione con i nostri clienti , la ricerca costante di nuovi materiali e affidabili componenti è sinonimo di qualità.

Alvise Piccoli

CEO & Funder

Professionalita' e cortesia

Da sempre la nostra attenzione ai suggerimenti , la collaborazione con i nostri clienti , la ricerca costante di nuovi materiali e affidabili componenti è sinonimo di qualità.

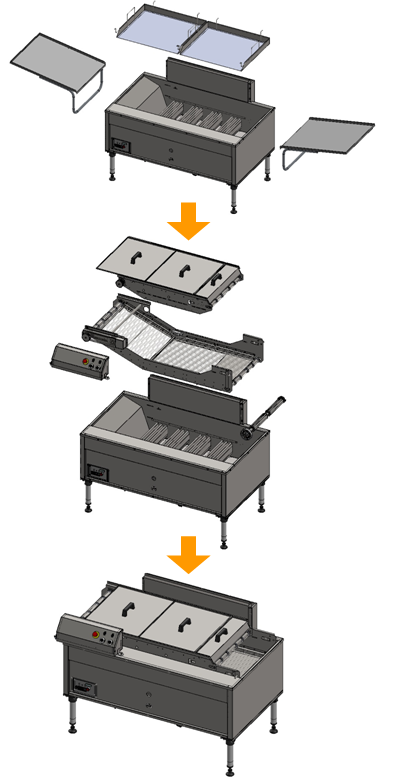

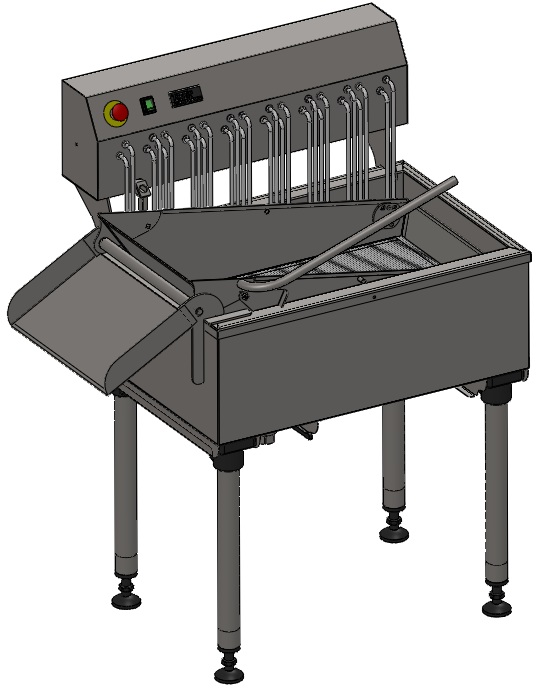

Hai bisogno di una macchina su misura.....

ABAR ricerca costante di nuovi materiali e affidabili componenti è sinonimo di qualità.

02.

ABAR LA SOLUZIONE CHE CERCAVI

Azienda industriale strutturata da piu' di 40 anni sul mercato.

Fondere le esperienze professionali ed umane

per creare una sinergia all’avanguardia in grado di guardare al futuro e collaborare con partner nazionali ed internazionali.

Creare macchine e strutture dall'alto valore aggiunto

che riflettano le visioni dei clienti più esigenti e si sposino in modo armonico con l'ambiente circostante